- 光学麦克风

- 光学麦克风

- 光学水听器

- 宽带超声源 TAE

- 超声激励激光器

- 工作站 LEAsys

- 过程监控 PM Bundle

- 特种光纤

- 空芯光子晶体光纤 HCPCF

- 保偏掺镱光纤

- 铒镱共掺光纤

- 掺钕光纤

- 掺铥光纤

- 铥钬共掺光纤

- 镀铝光纤

- 镀金光纤

- 紫外|可见光光纤

- 可见|红外光光纤

- 特种光纤定制

- 超快激光传输

- 空芯光子晶体光纤

- 超快空芯跳线

- 超快传能光缆

- 超快传能系统

- 光栅|晶体

- 啁啾布拉格光栅 CBG

- 反射式体布拉格光栅 RBG

- 透射式体布拉格光栅 TBG

- FBG

- CFBG 定制刻栅

- CLBO 晶体

- PP-LBGO 晶体

- 激光器

- 飞秒脉冲压缩器 Fastlas

- 超快激光模块 1030nm

- 高功率超快激光器 1030nm

- 多谱线激光器 250-950nm

- 深紫外激光器 193nm

- 单频全固态激光器 266nm

- 高重频固体激光器 447nm|671nm|1342nm

- 线偏振单频激光器 1550nm

- 激光二极管

- 增透膜镀膜激光二极管

- 探测器

- 高速光电探测器 145GHz

- 平衡光电探测器 100GHz

- 高功率光电探测器 65GHz

- 单光子雪崩二极管 SPAD

- 超导纳米线单光子探测器

- 微焦点X射线源

- 位移台

- 精密六足位移台

- 纳米定位平台

- 偏摆台

- 线性平台

- 太赫兹

- 相机

- 半导体制冷器

- 单层 TEC

- 双层 TEC

- 多层 TEC

- 过程监控

- 激光工艺软件

- 激光加工质量监测

-

-

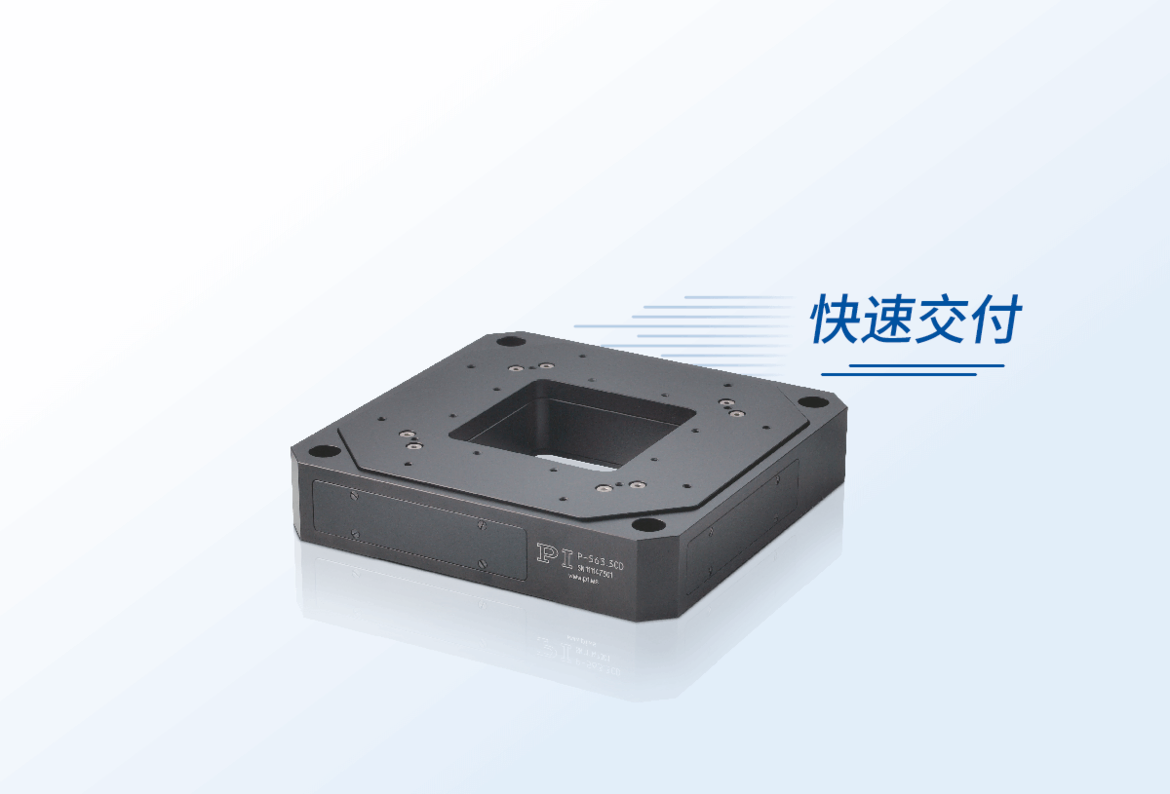

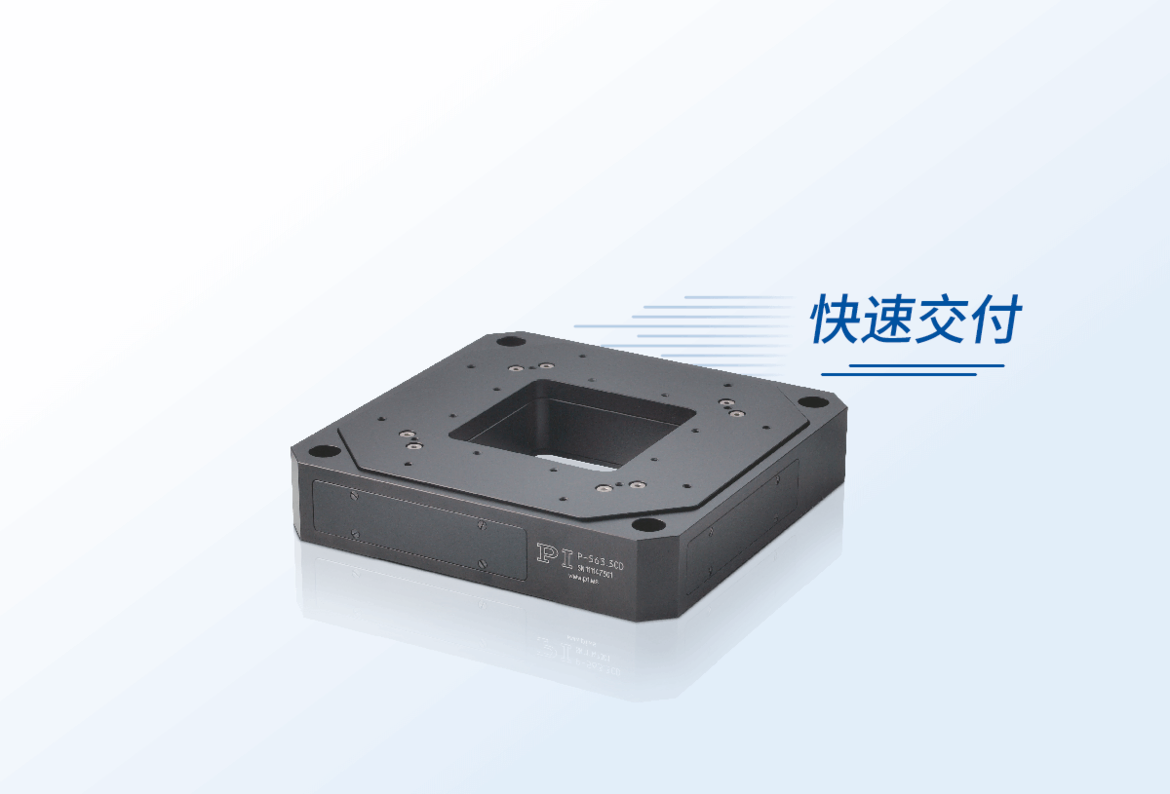

PIMars 纳米定位平台

X、Y 轴采用并联运动学设计,响应速度更快,多轴定位精度更高

行程范围可达 300×300×300 µm

电容式传感器确保极高线性度

无间隙高精度柔性导轨,扫描平面度优异

XYZ 版本具备高动态性能

通光孔径 66 mm×66 mm

采用 PICMA® 压电执行器,使用寿命卓越

应用领域: 扫描显微镜、掩模 / 晶圆定位、干涉测量、测量技术、生物技术、扫描与筛选

-

0.000.00

X、Y 轴采用并联运动学设计,响应速度更快,多轴定位精度更高

行程范围可达 300×300×300 µm

电容式传感器确保极高线性度

无间隙高精度柔性导轨,扫描平面度优异

XYZ 版本具备高动态性能

通光孔径 66 mm×66 mm

采用 PICMA® 压电执行器,使用寿命卓越

应用领域: 扫描显微镜、掩模 / 晶圆定位、干涉测量、测量技术、生物技术、扫描与筛选

PICMA® 压电执行器,使用寿命卓越:PICMA® 压电执行器采用全陶瓷绝缘设计,可有效抵御湿气影响,避免因漏电流增大导致的故障。相较于传统聚合物绝缘执行器,其使用寿命延长至 10 倍,可实现 1000 亿次循环无故障运行。

电容式传感器,亚纳米级分辨率:电容式传感器采用非接触式测量,分辨率可达亚纳米级,确保运动具备出色的线性度、长期稳定性,且带宽达到 kHz 级别。

无间隙柔性导轨,导向精度高:柔性导轨无需维护、无摩擦、无磨损,且无需润滑。其高刚度特性保证了高负载能力,同时抗冲击、抗振动,可在宽温度范围内稳定工作。

自动配置,组件快速更换:机械结构与控制器可按需组合并快速更换。所有伺服参数和线性化参数均存储在机械结构 D-sub 连接器的 ID 芯片中,数字控制器的自动校准功能在每次开机时都会自动调用这些数据。

并联位置测量,纳米级跟踪精度:所有自由度均相对于单一固定参考点进行测量,可实时主动补偿轴间非期望串扰(主动导向,取决于带宽)。即使在动态运行状态下,也能实现纳米级的高跟踪精度。

**详细参数见规格书

| Motion | Unit | Tolerance | P-561.3CD | P-561.3CL | P-562.3CD | P-562.3CL | P-563.3CD | P-563.3CL | P-561.3DD |

| --- | --- | --- | --- | --- | --- | --- | --- | --- | --- |

| Active axes | | | X | Y | Z | X | Y | Z | X | Y | Z | X | Y | Z | X | Y | Z | X | Y | Z | X | Y | Z |

| Travel range in X | µm | | 100 | 100 | 200 | 200 | 300 | 300 | 45 |

| Travel range in Y | µm | | 100 | 100 | 200 | 200 | 300 | 300 | 45 |

| Travel range in Z | µm | | 100 | 100 | 200 | 200 | 300 | 300 | 15 |

| Travel range in X, open loop, at -20 to 120 V | µm | +20 % / -0 % | 150 | 150 | 300 | 300 | 340 | 340 | 58 |

| Travel range in Y, open loop, at -20 to +120 V | µm | +20 % / -0 % | 150 | 150 | 300 | 300 | 340 | 340 | 58 |

| Travel range in Z, open loop, at -20 to 120 V | µm | +20 % / -0 % | 150 | 150 | 300 | 300 | 340 | 340 | 18 |

| Linearity error in X | % | Max. | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 |

| Linearity error in Y | % | Max. | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 |

| Linearity error in Z | % | Max. | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.08 |

| Straightness error E\_XZ | nm | Typ. | ±30 | ±30 | ±50 | ±50 | ±50 | ±50 | ±20 |

| Straightness error E\_YZ | nm | Typ. | ±30 | ±30 | ±50 | ±50 | ±50 | ±50 | ±20 |

| Straightness error E\_ZX (flat- ness) | nm | Typ. | ±15 | ±15 | ±20 | ±20 | ±25 | ±25 | ±10 |

| Straightness error E\_ZY (flat- ness) | nm | Typ. | ±15 | ±15 | ±20 | ±20 | ±25 | ±25 | ±10 |

| Angular error E\_AY (pitch) | µrad | Typ. | ±1 | ±1 | ±2 | ±2 | ±2 | ±2 | ±3 |

| Angular error E\_AZ | µrad | Typ. | ±15 | ±15 | ±20 | ±20 | ±25 | ±25 | ±3 |

| Angular error E\_BX (pitch) | µrad | Typ. | ±1 | ±1 | ±2 | ±2 | ±2 | ±2 | ±3 |

| Angular error E\_BZ | µrad | Typ. | ±15 | ±15 | ±20 | ±20 | ±25 | ±25 | ±3 |

| Angular error E\_CX (yaw) | µrad | Typ. | ±6 | ±6 | ±10 | ±10 | ±10 | ±10 | ±3 |

| Angular error E\_CY (yaw) | µrad | Typ. | ±6 | ±6 | ±10 | ±10 | ±10 | ±10 | ±3 || Motion | Unit | Tolerance | P-561.3CD | P-561.3CL | P-562.3CD | P-562.3CL | P-563.3CD | P-563.3CL | P-561.3DD |

| --- | --- | --- | --- | --- | --- | --- | --- | --- | --- |

| Active axes | | | X | Y | Z | X | Y | Z | X | Y | Z | X | Y | Z | X | Y | Z | X | Y | Z | X | Y | Z |

| Travel range in X | µm | | 100 | 100 | 200 | 200 | 300 | 300 | 45 |

| Travel range in Y | µm | | 100 | 100 | 200 | 200 | 300 | 300 | 45 |

| Travel range in Z | µm | | 100 | 100 | 200 | 200 | 300 | 300 | 15 |

| Travel range in X, open loop, at -20 to 120 V | µm | +20 % / -0 % | 150 | 150 | 300 | 300 | 340 | 340 | 58 |

| Travel range in Y, open loop, at -20 to +120 V | µm | +20 % / -0 % | 150 | 150 | 300 | 300 | 340 | 340 | 58 |

| Travel range in Z, open loop, at -20 to 120 V | µm | +20 % / -0 % | 150 | 150 | 300 | 300 | 340 | 340 | 18 |

| Linearity error in X | % | Max. | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 |

| Linearity error in Y | % | Max. | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 |

| Linearity error in Z | % | Max. | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.08 |

| Straightness error E\_XZ | nm | Typ. | ±30 | ±30 | ±50 | ±50 | ±50 | ±50 | ±20 |

| Straightness error E\_YZ | nm | Typ. | ±30 | ±30 | ±50 | ±50 | ±50 | ±50 | ±20 |

| Straightness error E\_ZX (flat- ness) | nm | Typ. | ±15 | ±15 | ±20 | ±20 | ±25 | ±25 | ±10 |

| Straightness error E\_ZY (flat- ness) | nm | Typ. | ±15 | ±15 | ±20 | ±20 | ±25 | ±25 | ±10 |

| Angular error E\_AY (pitch) | µrad | Typ. | ±1 | ±1 | ±2 | ±2 | ±2 | ±2 | ±3 |

| Angular error E\_AZ | µrad | Typ. | ±15 | ±15 | ±20 | ±20 | ±25 | ±25 | ±3 |

| Angular error E\_BX (pitch) | µrad | Typ. | ±1 | ±1 | ±2 | ±2 | ±2 | ±2 | ±3 |

| Angular error E\_BZ | µrad | Typ. | ±15 | ±15 | ±20 | ±20 | ±25 | ±25 | ±3 |

| Angular error E\_CX (yaw) | µrad | Typ. | ±6 | ±6 | ±10 | ±10 | ±10 | ±10 | ±3 |

| Angular error E\_CY (yaw) | µrad | Typ. | ±6 | ±6 | ±10 | ±10 | ±10 | ±10 | ±3 |

| Motion | Unit | Tolerance | P-561.3CD | P-561.3CL | P-562.3CD | P-562.3CL | P-563.3CD | P-563.3CL | P-561.3DD |

| --- | --- | --- | --- | --- | --- | --- | --- | --- | --- |

| Active axes | | | X | Y | Z | X | Y | Z | X | Y | Z | X | Y | Z | X | Y | Z | X | Y | Z | X | Y | Z |

| Travel range in X | µm | | 100 | 100 | 200 | 200 | 300 | 300 | 45 |

| Travel range in Y | µm | | 100 | 100 | 200 | 200 | 300 | 300 | 45 |

| Travel range in Z | µm | | 100 | 100 | 200 | 200 | 300 | 300 | 15 |

| Travel range in X, open loop, at -20 to 120 V | µm | +20 % / -0 % | 150 | 150 | 300 | 300 | 340 | 340 | 58 |

| Travel range in Y, open loop, at -20 to +120 V | µm | +20 % / -0 % | 150 | 150 | 300 | 300 | 340 | 340 | 58 |

| Travel range in Z, open loop, at -20 to 120 V | µm | +20 % / -0 % | 150 | 150 | 300 | 300 | 340 | 340 | 18 |

| Linearity error in X | % | Max. | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 |

| Linearity error in Y | % | Max. | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 |

| Linearity error in Z | % | Max. | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.08 |

| Straightness error E\_XZ | nm | Typ. | ±30 | ±30 | ±50 | ±50 | ±50 | ±50 | ±20 |

| Straightness error E\_YZ | nm | Typ. | ±30 | ±30 | ±50 | ±50 | ±50 | ±50 | ±20 |

| Straightness error E\_ZX (flat- ness) | nm | Typ. | ±15 | ±15 | ±20 | ±20 | ±25 | ±25 | ±10 |

| Straightness error E\_ZY (flat- ness) | nm | Typ. | ±15 | ±15 | ±20 | ±20 | ±25 | ±25 | ±10 |

| Angular error E\_AY (pitch) | µrad | Typ. | ±1 | ±1 | ±2 | ±2 | ±2 | ±2 | ±3 |

| Angular error E\_AZ | µrad | Typ. | ±15 | ±15 | ±20 | ±20 | ±25 | ±25 | ±3 |

| Angular error E\_BX (pitch) | µrad | Typ. | ±1 | ±1 | ±2 | ±2 | ±2 | ±2 | ±3 |

| Angular error E\_BZ | µrad | Typ. | ±15 | ±15 | ±20 | ±20 | ±25 | ±25 | ±3 |

| Angular error E\_CX (yaw) | µrad | Typ. | ±6 | ±6 | ±10 | ±10 | ±10 | ±10 | ±3 |

| Angular error E\_CY (yaw) | µrad | Typ. | ±6 | ±6 | ±10 | ±10 | ±10 | ±10 | ±3 || Motion | Unit | Tolerance | P-561.3CD | P-561.3CL | P-562.3CD | P-562.3CL | P-563.3CD | P-563.3CL | P-561.3DD |

| --- | --- | --- | --- | --- | --- | --- | --- | --- | --- |

| Active axes | | | X | Y | Z | X | Y | Z | X | Y | Z | X | Y | Z | X | Y | Z | X | Y | Z | X | Y | Z |

| Travel range in X | µm | | 100 | 100 | 200 | 200 | 300 | 300 | 45 |

| Travel range in Y | µm | | 100 | 100 | 200 | 200 | 300 | 300 | 45 |

| Travel range in Z | µm | | 100 | 100 | 200 | 200 | 300 | 300 | 15 |

| Travel range in X, open loop, at -20 to 120 V | µm | +20 % / -0 % | 150 | 150 | 300 | 300 | 340 | 340 | 58 |

| Travel range in Y, open loop, at -20 to +120 V | µm | +20 % / -0 % | 150 | 150 | 300 | 300 | 340 | 340 | 58 |

| Travel range in Z, open loop, at -20 to 120 V | µm | +20 % / -0 % | 150 | 150 | 300 | 300 | 340 | 340 | 18 |

| Linearity error in X | % | Max. | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 |

| Linearity error in Y | % | Max. | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 |

| Linearity error in Z | % | Max. | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.08 |

| Straightness error E\_XZ | nm | Typ. | ±30 | ±30 | ±50 | ±50 | ±50 | ±50 | ±20 |

| Straightness error E\_YZ | nm | Typ. | ±30 | ±30 | ±50 | ±50 | ±50 | ±50 | ±20 |

| Straightness error E\_ZX (flat- ness) | nm | Typ. | ±15 | ±15 | ±20 | ±20 | ±25 | ±25 | ±10 |

| Straightness error E\_ZY (flat- ness) | nm | Typ. | ±15 | ±15 | ±20 | ±20 | ±25 | ±25 | ±10 |

| Angular error E\_AY (pitch) | µrad | Typ. | ±1 | ±1 | ±2 | ±2 | ±2 | ±2 | ±3 |

| Angular error E\_AZ | µrad | Typ. | ±15 | ±15 | ±20 | ±20 | ±25 | ±25 | ±3 |

| Angular error E\_BX (pitch) | µrad | Typ. | ±1 | ±1 | ±2 | ±2 | ±2 | ±2 | ±3 |

| Angular error E\_BZ | µrad | Typ. | ±15 | ±15 | ±20 | ±20 | ±25 | ±25 | ±3 |

| Angular error E\_CX (yaw) | µrad | Typ. | ±6 | ±6 | ±10 | ±10 | ±10 | ±10 | ±3 |

| Angular error E\_CY (yaw) | µrad | Typ. | ±6 | ±6 | ±10 | ±10 | ±10 | ±10 | ±3 |